Understanding Diecasting: The Course of and Its Applications

Understanding Diecasting: The Course of and Its Applications

Blog Article

Diecasting is a pivotal process for modern manufacturing. It plays an important part in the production of complicated metal parts that are produced with precision and efficacy. This method involves forcing the molten metal with high pressure into a mold, producing parts with exceptional dimensional accuracy and high finish on the surface. With the development of industries and the demand for high-quality components expands, diecasting will continue to show its merits, particularly in sectors requiring massive production of highly intricate components. This article explores the process of diecasting it's advantages, the benefits of diecasting, materials alternatives, and extensive application across a variety of sectors.

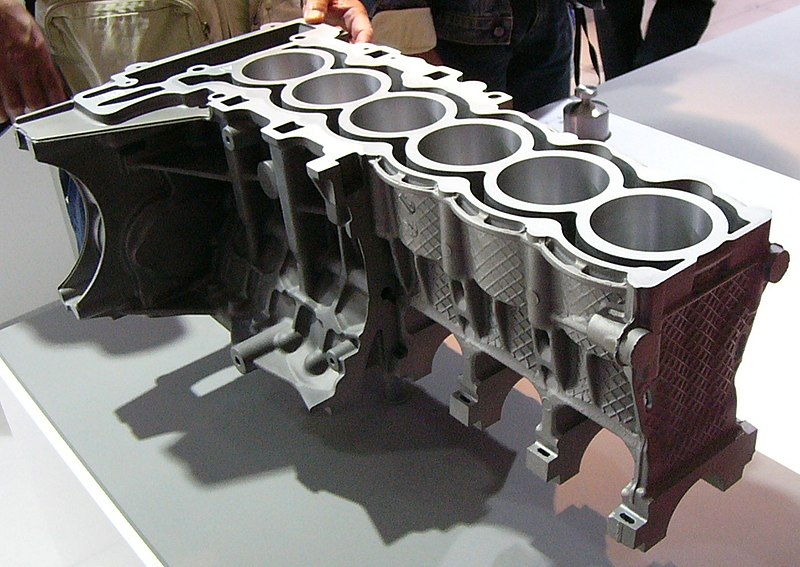

Diecasting starts by creating a mold, known as a "die," which is made of hardened steel for a long time to endure high pressures and temperatures. When the mold is made Metal alloys such as aluminum, zinc, magnesium or copper, are heated until they become molten. This molten metal is then put into the mold under high pressure, ensuring it is able to fill all areas of the mold, which includes detailed sections and thin walls. The pressure is maintained until the metal solidifies, and at that point, the mold is opened, and the part that has been formed is ejected. The high pressure method guarantees that your final product is exact that it requires little extra machining or final.

One of the major advantages of using diecasting is its ability to produce high volumes of parts. Once the dies are created it is possible to have the process repeated many times, with little deviation between parts. This repeatability is essential to industries that require huge numbers of identical parts. Additionally, diecasting is renowned as a material that is efficient. Diecasting produces less waste than other methods of metal forming since any scrap metal is able to be reused and recycled. This reduces not just the cost of material but also promotes green manufacturing practices. Diecasting's speed and precision diecasting makes it a great alternative for the production of large volumes of components quickly and efficiently making sure that companies can adhere to tight schedules for production and market demands.

Diecasting is also a great method of producing products with exceptional mechanical characteristics. The rapid cooling of the melting metal in the process of casting results in fine grain structure that increases the strength and durability of the final product. Dies makes diecast parts well-suited for projects that require high performance and reliability. For example, in the automobile industry, diecast parts are used in the transmissions, engines and structural components. the strength-to-weight ratio is crucial for vehicle efficiency and safety. In aerospace diecast elements contribute to the creation of light but strong structures, crucial for optimizing fuel efficiency and performance. To obtain supplementary details kindly visit www.senadiecasting.com.my/

Diecasting's flexibility extends to a wide array of possibilities. In the auto industry Diecast parts are utilized in the transmissions, engines and other structural parts. They contribute to lighter and more fuel-efficient vehicles. In the electronics industry, diecasting is utilized to make housings, heatsinks, as well as connectors that ensure the best performance in thermal management as well as durability. Household appliances, power tools and even toys profit from diecasting's precision and efficiency, with parts ranging from knobs and handles all the way to internal mechanisms. The process's adaptability to various metals and its ability to create parts that have intricate design make it suitable to a variety of industries, all profiting from the distinct advantages the process offers.

Diecasting is an incredibly productive and flexible manufacturing method that is integral to producing complicated metal parts that have the highest precision and uniformity. Its capacity to design parts with intricate details precise tolerances, perfect tolerances, as well as polished surfaces makes it invaluable across various industries ranging from automotive and aerospace, to consumer electronics, and more. The use of different materials further enhances the versatility that diecasting offers, allowing companies to select the best alloy that meets their particular needs. As technology advances and the demand for high-quality, affordable components increases and increase, diecasting will continue to be crucial for manufacturing which will drive innovation and superiority when it comes to production.